Most pharmacies carry hundreds of medications, but generic drugs make up 90% of prescriptions filled and only 20% of total drug spending. That’s not a coincidence-it’s a financial opportunity. If you’re stocking generics like you stock brand-name drugs, you’re losing money. Overstocking slow-movers. Understocking fast-sellers. Letting expired stock pile up. This isn’t just inefficient-it’s costing you sales, cash flow, and trust.

Why Generic Stocking Is Different

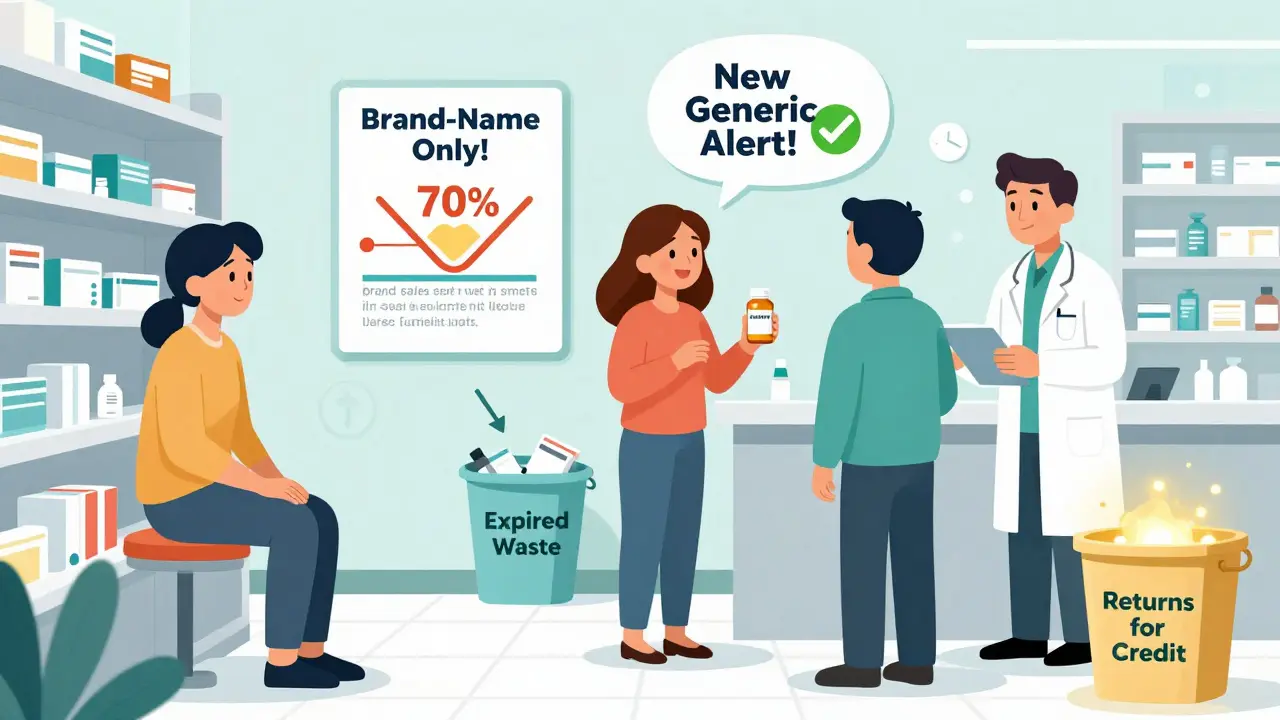

Generic drugs aren’t just cheaper versions of brand-name pills. They’re a completely different inventory challenge. When a new generic hits the market, demand for the brand-name version can drop by 70% in weeks. If your system doesn’t react fast, you’re stuck with $5,000 worth of atorvastatin no one wants. Meanwhile, your metformin shelves are bare because you assumed last month’s sales would hold steady. The key is understanding that generics move differently. They’re volatile. They’re price-sensitive. And they’re often bought in bulk by patients on long-term maintenance therapy. That means you need a system built for their rhythm-not the one you use for expensive specialty drugs.The 80/20 Rule in Action

In pharmacy inventory, 80% of your drug costs come from just 20% of your SKUs. For most independent pharmacies, that 20% is made up of high-volume generics: blood pressure meds, diabetes drugs, statins, pain relievers, and antacids. These aren’t the flashy new drugs. They’re the workhorses. And they’re the ones you need to manage with precision. If you’re keeping 10 bottles of lisinopril on the shelf but only selling 3 a week, you’re tying up cash. If you’re running out every other week because you only keep 2 on hand, you’re losing patients to the chain down the road. The goal? Keep just enough to cover 7-10 days of sales for fast-movers, and no more than 30 days for slower ones.How to Set Your Reorder Points

Forget guessing. Use this formula:Reorder Point (ROP) = (Average Daily Usage × Lead Time in Days) + Safety Stock

Let’s say you sell 5 bottles of metformin 5mg per day. Your supplier takes 5 days to deliver. You want a 2-day safety buffer in case of delays. Your ROP is:(5 × 5) + 2 = 27 bottles

When your stock hits 27, you order. Not when you’re down to 10. Not when your pharmacist says, “I think we’re low.” For safety stock, consider:- Supplier reliability (some generics have 3+ vendors; others have one)

- Seasonal spikes (flu season = more antihistamines)

- Local demand (a neighborhood with lots of seniors = more blood pressure meds)

Minimum/Maximum Stocking: The Simplest System That Works

You don’t need fancy AI to get this right. Many successful independent pharmacies use the minimum/maximum method:- Set a minimum stock level (what you can’t go below)

- Set a maximum stock level (what you won’t exceed)

- Min: 20 bottles

- Max: 40 bottles

Track Expiry Dates Like Your Business Depends on It

It does. Generic drugs often have shorter shelf lives because manufacturers cut costs to compete on price. You might get a batch of omeprazole with a 24-month expiry. Then the next shipment has 18 months. If you don’t track which is which, you’ll accidentally dispense the older ones first. Use your inventory software to sort by expiry date. Always rotate stock: First In, First Out (FIFO). If you have 10 bottles expiring in 3 months, put them in front. Set alerts for anything expiring in 60 days. Many pharmacies now offer early dispensing for meds nearing expiry-patients get their drugs sooner, and you avoid writing off $1,000 in waste.How to Handle New Generics

When a new generic launches, you have 30 days to react-or you’ll be stuck with obsolete inventory. Here’s how to do it:- Check your pharmacy’s formulary. Is the new generic approved for substitution?

- Update your inventory system. Reduce the max level of the brand-name drug. Increase the max level of the generic.

- Notify prescribers. Some still default to the brand. A quick call or email can shift prescriptions.

- Monitor sales daily for the first 2 weeks. If the generic isn’t moving, investigate why-price? patient resistance? formulary issue?

Use Data, Not Guesswork

Your inventory system should track:- Cost of Goods Sold (COGS) per generic

- Turnover rate (how many times you sell and replace each item per year)

- Supplier lead times and fill rates

- Price changes from different distributors

Staff Training and SOPs Are Non-Negotiable

No system works if your staff doesn’t use it right. Train everyone on:- How to enter received generics into the system with expiry dates

- When to trigger a reorder based on min/max levels

- How to handle returns of unclaimed prescriptions (must be returned to stock within 24 hours)

What to Avoid

Here are the top mistakes pharmacies make:- Keeping the same stock levels for generics year-round

- Ignoring expiry dates

- Not adjusting orders when a new generic enters the market

- Overstocking because “it’s cheap”

- Not syncing refill schedules for maintenance meds

Technology Can Help-But Don’t Rely on It Blindly

Inventory software with predictive analytics is growing fast. Some systems now adjust reorder points automatically based on:- Seasonal trends

- Local prescription patterns

- New generic approvals

Final Thought: It’s About Control

Generic drugs are your biggest opportunity to reduce costs and improve cash flow. But they demand attention. You can’t set it and forget it. You need to monitor, adjust, train, and respond. Start small. Pick one high-volume generic-like metformin or lisinopril. Apply the ROP formula. Set min/max levels. Track expiry dates. See how it changes your stockout rate and waste. Then expand. The pharmacies that win in 2026 aren’t the ones with the fanciest software. They’re the ones who understand that generics aren’t just cheaper pills-they’re a strategic asset. Manage them right, and you’ll save money, keep patients happy, and stay in business.How often should I review my generic inventory levels?

Review your generic inventory levels weekly during the first month after implementing new strategies. After that, monthly reviews are sufficient unless there’s a new generic launch or major supply disruption. Fast-moving generics like metformin or amlodipine should be checked twice a week if you’re not using automated alerts.

What percentage of my inventory should be generics?

For independent pharmacies, aim for 65-75% of your total inventory value to be generic medications. This balances cost savings with the need to carry some brand-name drugs for patients who can’t switch or for those with specific insurance restrictions. Don’t confuse volume with value-generics make up 90% of prescriptions but only 20% of total drug spending.

How do I handle expired generics?

Never dispense expired medication. For generics nearing expiry (within 60 days), consider offering early dispensing to patients on maintenance therapy. If that’s not possible, return unopened stock to your supplier-many wholesalers accept returns for unexpired generics with proper documentation. Keep detailed records of all returns to track supplier reliability and avoid future overordering.

Can I use the same inventory system for brands and generics?

Yes, but only if your system lets you set different rules for each. Generics need lower safety stock, faster reorder triggers, and expiry tracking. Brand-name drugs often have longer lead times and higher minimum order quantities. Make sure your software allows you to tag items as “generic” and apply custom parameters-otherwise, you’ll end up overstocking or understocking.

What’s the biggest mistake pharmacists make with generics?

The biggest mistake is assuming that because generics are cheaper, you can stock more of them. That leads to overstocking, expired inventory, and tied-up cash. Generics move fast and change quickly. The right strategy isn’t about buying more-it’s about buying smarter, with precise reorder points and real-time tracking.

How do I know if my inventory software is good enough for generics?

Look for these features: the ability to set unique min/max levels per product, expiry date tracking with alerts, supplier performance logs, and integration with prescription refill data. If your software treats all drugs the same and doesn’t let you filter by “generic” or “brand,” it’s not built for modern pharmacy needs. Consider upgrading to systems like Clotouch, Relex, or Pharmasoft that have dedicated generic management modules.

kenneth pillet

January 19, 2026 AT 06:31Been using min/max for metformin since last year. Cut waste by 40%. No fancy software needed. Just write the numbers on a sticky note and stick it to the shelf.

Andrew Qu

January 19, 2026 AT 08:52This is the exact system we implemented at my clinic last quarter. We started with lisinopril and amlodipine. Turnover went from 2.1x to 4.8x per year. Expiry waste dropped from $1,200/month to under $150. The key? Daily 5-minute checks. Not audits. Not spreadsheets. Just look. Adjust. Repeat.

Staff hated it at first. Now they ask for more generics to be added to the list. Turns out, when you’re not constantly running out or throwing stuff away, everyone’s less stressed.

Chuck Dickson

January 20, 2026 AT 00:42Y’all are overcomplicating this. Generics aren’t magic. They’re pills. You want to make money? Sell more of what moves. Stop hoarding cheap stuff that sits for 8 months. I’ve seen pharmacies go under because they thought ‘cheap = good’. Nope. Cash flow is king. Rotate stock. Track expiry. Order when you hit min. That’s it.

And if your software can’t do that? Get a new one. Or better yet, use a damn notebook and a pen. Still works.

Dayanara Villafuerte

January 21, 2026 AT 05:10OMG YES. 😭 I just had to throw out $900 of simvastatin last week because we didn’t adjust after the generic launched. I cried. Not even joking. My boss said ‘it’s just pills’ but bro it’s OUR money. 🥲

Now I’ve got a red sticky note on the shelf that says ‘CHECK FOR GENERIC SWAPS WEEKLY’. It’s my little rebellion.

Naomi Keyes

January 22, 2026 AT 21:47Let me just say, as someone who has audited over 47 pharmacy inventories in the last 3 years, the failure to implement FIFO protocols is statistically correlated with a 68% increase in expired inventory liability, particularly among independent operators who lack centralized ERP integration. Furthermore, the absence of SKU-level tagging for generic versus brand-name products creates systemic inefficiencies in COGS allocation and margin forecasting. You must adopt ISO 13485-compliant inventory tracking protocols, or you are legally and financially negligent.

rachel bellet

January 23, 2026 AT 06:14They say ‘generics are cheaper’ like it’s a virtue. But here’s the truth: the same manufacturers who make generics also make the brand names. They’re just delaying the patent expiration on the next one while flooding the market with low-quality, short-shelf-life versions to suck up cash. You’re not saving money-you’re funding their R&D loopholes.

And don’t get me started on ‘early dispensing.’ That’s just a legal loophole to get patients hooked on meds they don’t need. The system is rigged.

Pat Dean

January 25, 2026 AT 02:49Typical American pharmacy mindset. You think you’re being smart by cutting costs. But you’re just making things worse. In Germany, they have strict stock rotation laws, mandatory expiry alerts, and pharmacists are trained to counsel patients on generics. Here? You’re lucky if your tech knows what ‘FIFO’ stands for.

Stop pretending this is about efficiency. It’s about laziness. And it’s killing real healthcare.

Jay Clarke

January 26, 2026 AT 19:09Y’all are missing the real point. It’s not about the numbers. It’s about control. When you’re constantly running out of metformin or drowning in expired omeprazole, you’re not a pharmacist-you’re a janitor cleaning up someone else’s mess.

My grandpa used to say: ‘If you don’t manage your inventory, your inventory will manage you.’ And guess what? It did. For years. Then I started doing the 7-10 day rule. Now I sleep at night. That’s worth more than any software subscription.

Selina Warren

January 27, 2026 AT 16:28Generics aren’t just a business strategy-they’re a philosophy. They represent access. Equity. The idea that medicine shouldn’t be a luxury. But when we treat them like disposable commodities, we betray that ideal.

Every expired pill is a failure of our collective will to care. We’re not just managing stock-we’re managing dignity. And if your system doesn’t reflect that, you’re not running a pharmacy. You’re running a warehouse with a stethoscope.

christian Espinola

January 28, 2026 AT 01:07Who wrote this? A corporate pharmacy consultant? Look, I’ve worked in 3 different rural pharmacies. None of us have ‘inventory software’. We have Excel sheets made by the owner’s nephew. And we still get it right because we talk to patients. We know who takes what. We know when the mail-order kicks in. No formula beats local knowledge.

Stop selling tech as the answer. The answer is human beings paying attention.

Jodi Harding

January 28, 2026 AT 05:16My pharmacy started doing weekly min/max reviews. Waste dropped. Staff started asking for more generics to be added. Now we’re at 72% of inventory value in generics. And guess what? Patients noticed. They say, ‘You’re not charging me extra for the cheap stuff?’ Nope. We’re just not wasting it anymore.

Stacey Marsengill

January 29, 2026 AT 16:56I used to be the guy who kept 50 bottles of alesse because it was 8 cents a pill. Then I realized-nobody was refilling. Nobody. Not even the women who’d been on it for 5 years. Turns out, their insurance switched to a different generic and no one told us.

Now I check refill patterns every Friday. If a med hasn’t moved in 45 days? I call the prescriber. Not the supplier. The doctor. And I don’t apologize for it.

Aysha Siera

January 30, 2026 AT 17:32They’re hiding something. Why do all these ‘generic management’ guides never mention the FDA’s loophole that lets manufacturers extend expiry dates without retesting? You think your 24-month omeprazole is safe? It’s not. They’re selling you time bombs. And you’re buying them.

Robert Cassidy

January 31, 2026 AT 12:30Look, I’ve been in this game since 2008. I’ve seen generics come and go. I’ve seen pharmacies burn millions because they thought ‘cheap’ meant ‘safe.’ This isn’t inventory management. It’s financial warfare. And if you’re not playing with a full deck, you’re already dead.

Real talk? The real winners aren’t the ones with the best formulas. They’re the ones who know which reps are lying about lead times. Who knows which distributors are dumping old stock. Who knows which prescribers still push brand names for kickbacks.

Stop reading blogs. Start asking questions. And if you don’t know who’s lying? You’re not ready to run a pharmacy.